| | Coating characterization

Metallographic preparation

Examens microscopiques

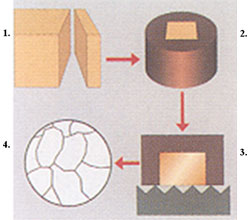

Cutting

Depending on the size or shape of a piece of material, it may need to be sectioned.

A plane surface, with as little deformation as possible, is required to facilitate and shorten further preparation.

Consequently, the most appropriate sectioning method is abrasive wet cutting, which will introduce the least amount of damage in relation to the cutting time needed.

Abrasive wet cutting employs a cut-off wheel consisting of an abrasive and a binder. Cooling liquid flushes the wheel to avoid damaging the sample with frictional heat. The coolant also removes debris from the cutting area.

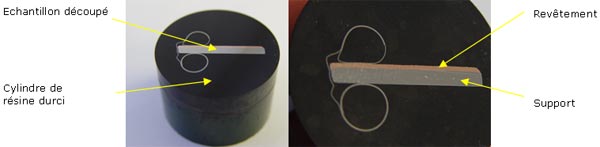

Hot Mounting

The sample is placed in the mounting press, the resin is added, and the sample is processed with heat and high pressure. This state lasts about 8 minutes (heating during 5 minutes and cooling for 3 minutes).

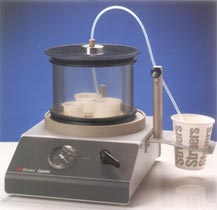

Vacuum Impregnation

Mechanical preparation

Mechanical preparation is divided into two operations: grinding and polishing.

The 4 steps, cutting, mounting grinding and polishing have to be systematically performed

to assure repeatability and reliability of the results

.

Top Top

|

|