| Techniques : | |

Flame spray process

Arc spray process

Plasma spray process

Detonation spray process

HVOF spray process (High Velocity Oxygen Fuel)

The cold gas dynamic spray process

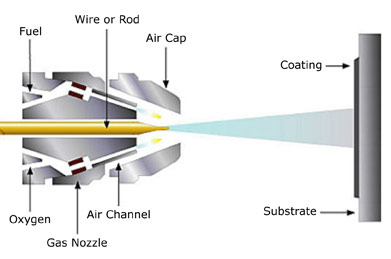

Among the thermal spray methods, the simplest and the cheapest way to deposit coatings is flame spraying. Both wire and powder can be used as a coating material.

The process relies on the chemical reaction between oxygen and a fuel of combustion (acetylene, hydrogen) to produce a heat source. This heat source creates a gas stream.

The feed stock material to be sprayed is fed into the flame in the form of a wire, and compressed air is then used to atomise the molten metal and accelerate particles onto the substrate.

The combustion powder process uses a similar technique, except that the wire feed stock is replaced with a powder.

The main advantage of the combustion powder thermal spray process is that a wide range of materials can be easily processed into powder from giving a larger choice of coatings.

The flame spray process is limited by materials with higher melting temperatures than the flame can provide or if the material decomposes on heating. Because of low flame temperature and particle velocity (40 m/s), coatings are usually porous and bond strength of deposits is low as well as adhesive strength between coating and substrate.

Top Top

|

|